If you have ever looked out of an airplane window, you have probably seen those huge engines hanging under the wings. Most modern airliners use something called a turbofan engine. It is one of the most efficient types of jet engines and it powers almost every commercial jet today. But how does it actually work?

The Basic Idea

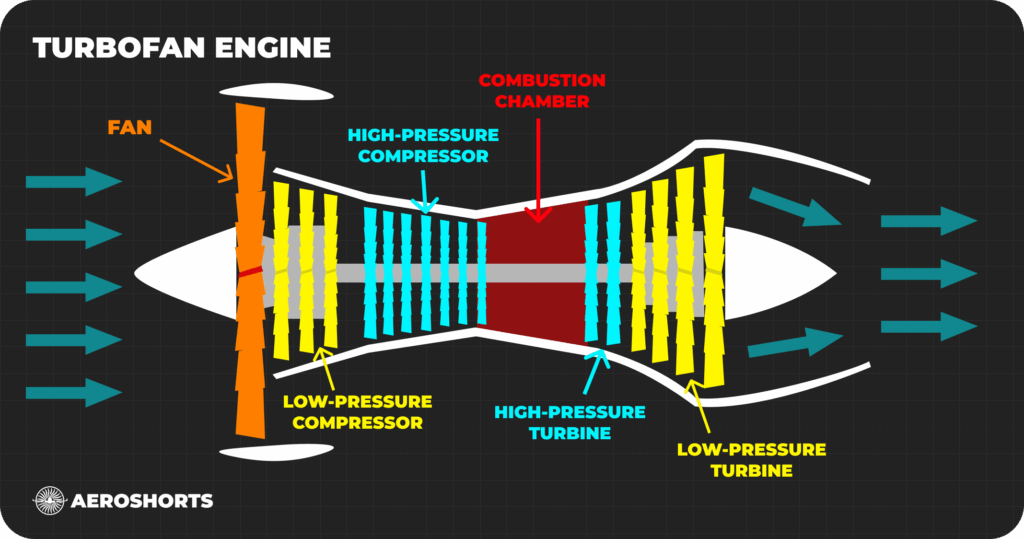

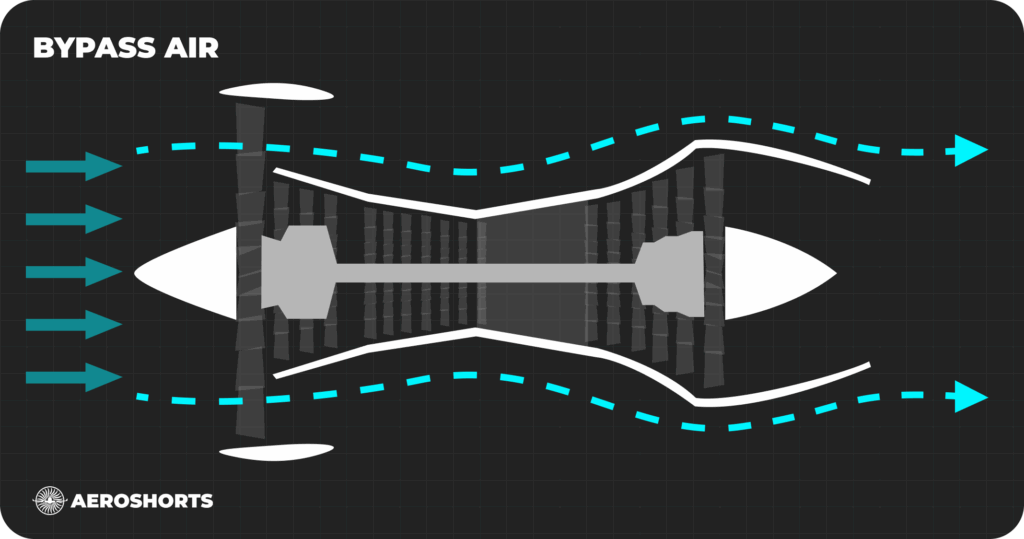

A turbofan engine is a type of jet engine that produces thrust by moving a large amount of air backward. Some of that air goes through the engine core, where fuel is burned, and the rest bypasses the core and flows around it. The combination of these two airflows gives the engine its name – “turbo” for the turbine and “fan” for the big fan at the front.

The Main Parts of a Turbofan

- Fan – The large fan at the front is the first thing you notice. It pulls in huge amounts of air. A part of this air (called the bypass air) goes around the core, while the rest goes inside to be compressed, mixed with fuel, and burned.

- Compressor – This section squeezes the incoming air to a much higher pressure. The air gets hotter and denser as it moves through several rotating blades.

- Combustion Chamber – Here, fuel is injected and mixed with the compressed air. When it burns, the gases expand rapidly and release a lot of energy.

- Turbine – The hot gases rush through the turbine blades, making them spin. The turbine is connected to the compressor and fan by a long shaft, so it provides the power needed to keep them turning.

- Exhaust Nozzle – Finally, the remaining gases exit the engine at high speed, creating thrust. This thrust pushes the aircraft forward.

The Bypass Ratio

One of the key terms when talking about turbofan engines is the bypass ratio. It describes how much air flows around the core compared to how much goes through it. A high bypass ratio means that a lot more air goes around the engine core. This makes the engine quieter and more fuel-efficient. That is why modern airliners have such large fans – they move more air with less fuel.

Why Turbofans Are So Efficient

Unlike older turbojets, turbofans combine two sources of thrust: the fan and the jet exhaust. The fan moves a large volume of air at a lower speed, while the jet exhaust pushes a smaller amount of air at very high speed. Moving a big mass of air slowly is generally more efficient than moving a small mass very fast. This is one of the main reasons turbofan engines dominate commercial aviation.

How It All Works Together

When the aircraft starts its takeoff roll, air enters the front fan. The compressor increases its pressure, the combustion chamber adds energy by burning fuel, and the turbine extracts that energy to keep the system running. The air that bypasses the core mixes with the exhaust gases at the back, creating a smooth and powerful stream of thrust.

The whole process follows the basic principle of Newton’s third law: every action has an equal and opposite reaction. The air pushed backward creates a forward force that propels the airplane.

In Short

A turbofan engine is an amazing piece of engineering that turns fuel and air into speed and lift. It is powerful, efficient, and surprisingly elegant in how it works. From the moment you hear the engines spool up before takeoff, remember that inside those engines, air is being compressed, ignited, and accelerated to carry hundreds of people across the sky.